How to launch a physical product

I have this image saved on my home computer that I look at whenever I’m frustrated with my business. It’s called “happy.jpg” and sits in the upper right of my desktop.

It never moves and it’s always there when I need it.

At first glance, it’s not a particularly noteworthy picture. It’s just me, smiling.

Here it is:

What you don’t see in that picture is why I’m smiling.

After five long years of trying to get my product manufactured, I was receiving my first large order from my manufacturer at my home in Indiana.

Here’s the thing about happy moments in business: Even with the added context, what you still don’t see in either of those photos are all of the times that I wanted to quit. That first photo reminds me of the pure satisfaction of wading through all of the highs and lows, having created something that I could actually touch and hold.

It seems like, lately, all that people are talking about is digital products. And I get it. I really do. The margins are great. They’re easy to make. They’re even easier to sell.

But what if the thing that you want to make is a physical thing? What if, like me, you’re obsessed with creating something you can hold in your hands?

Here’s the thing about launching a physical product:

- It’s

difficultnearly impossible to get it manufactured - It’s expensive

- Margins are tight

- You might lose everything

Maybe you read all of these things and you still want to try it.

While you may feel lost in the wilderness now, I can save you all of the headaches that I went through building my $100,000 business, Ok! Kimonos. By the end, you’ll know the next steps to take to bring your physical product to life. And I’ve included links below so you can skip to the right section if you’re having a specific problem.

How do I find somebody to manufacture my physical product?

As the world’s largest marketplace of physical product exporters, China-based Alibaba is one of the best places to start looking for product suppliers. Alibaba is an online marketplace for sourcing overseas manufacturers and is best if the base product is something new, unique, or rare (like a kimono). But if you’re looking for something mainstream, like a t-shirt printing company, find somebody local or start with Threadbird (they’re the best I’ve ever worked with).

A short guide to finding suppliers on Alibaba

Alibaba can be extremely confusing when you first start, for lots of reasons. But mainly it’s impossible to figure out who you can trust. Mainly because it seems like they investigate the suppliers ahead of time … but they actually don’t.

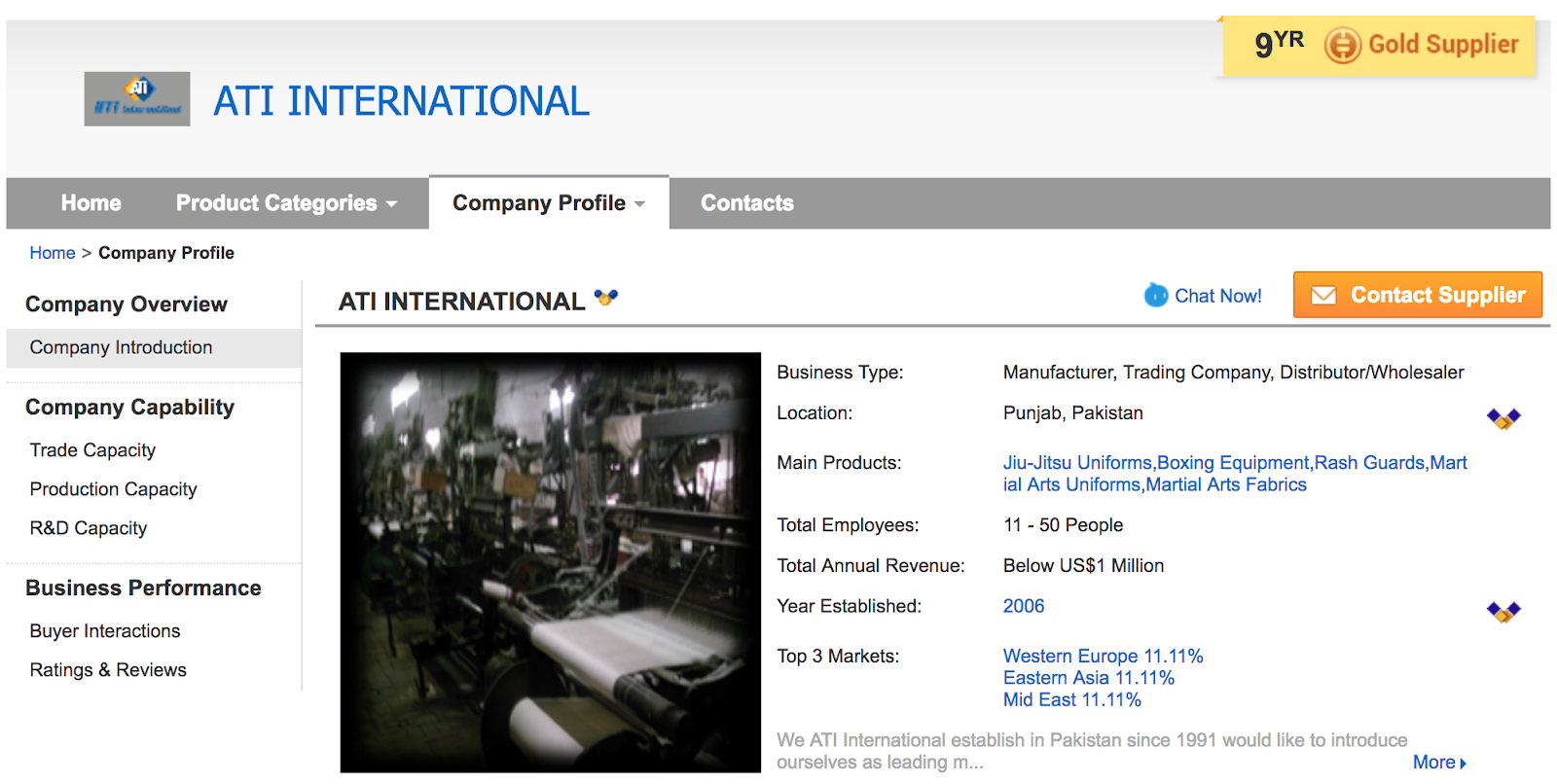

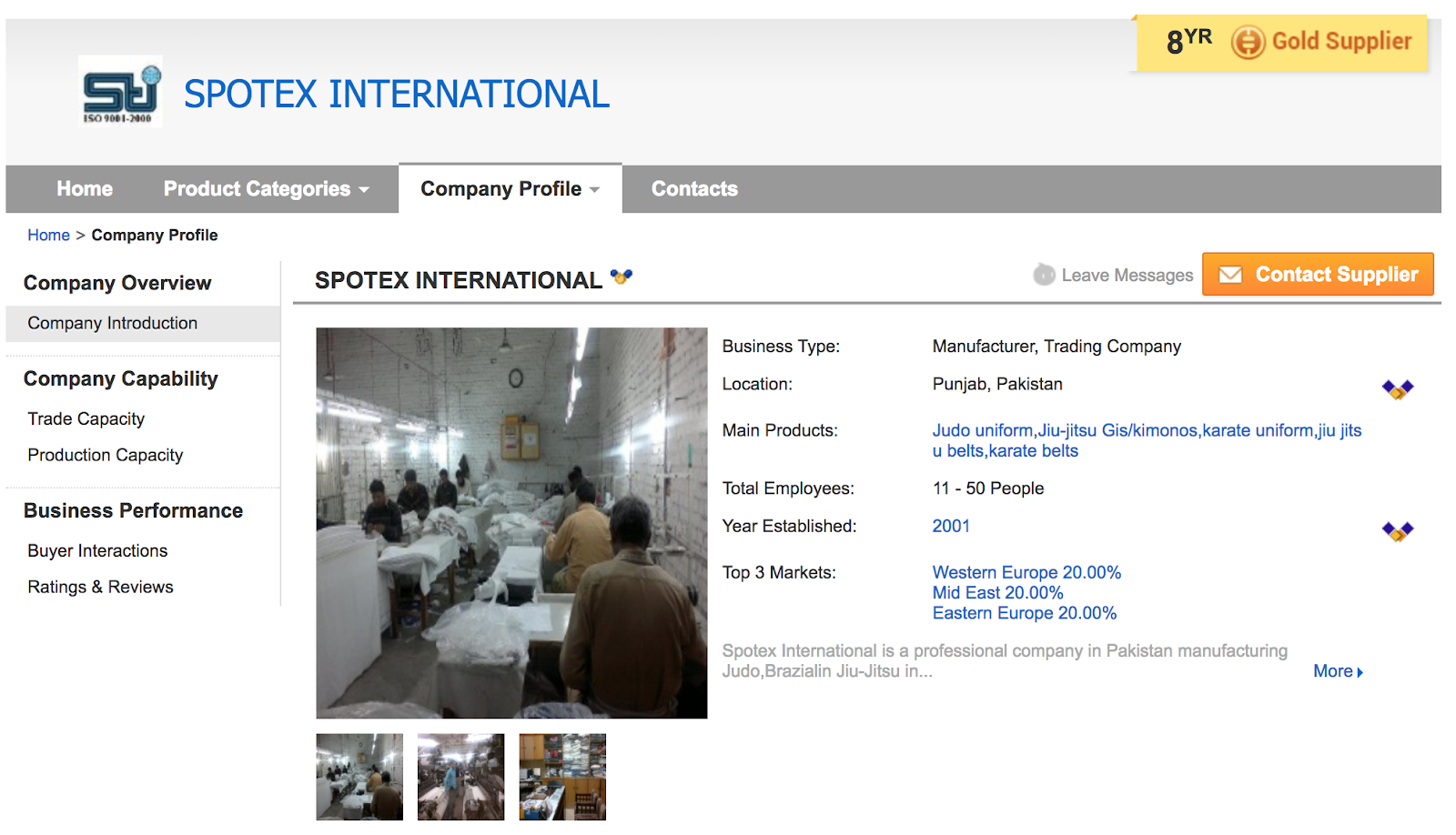

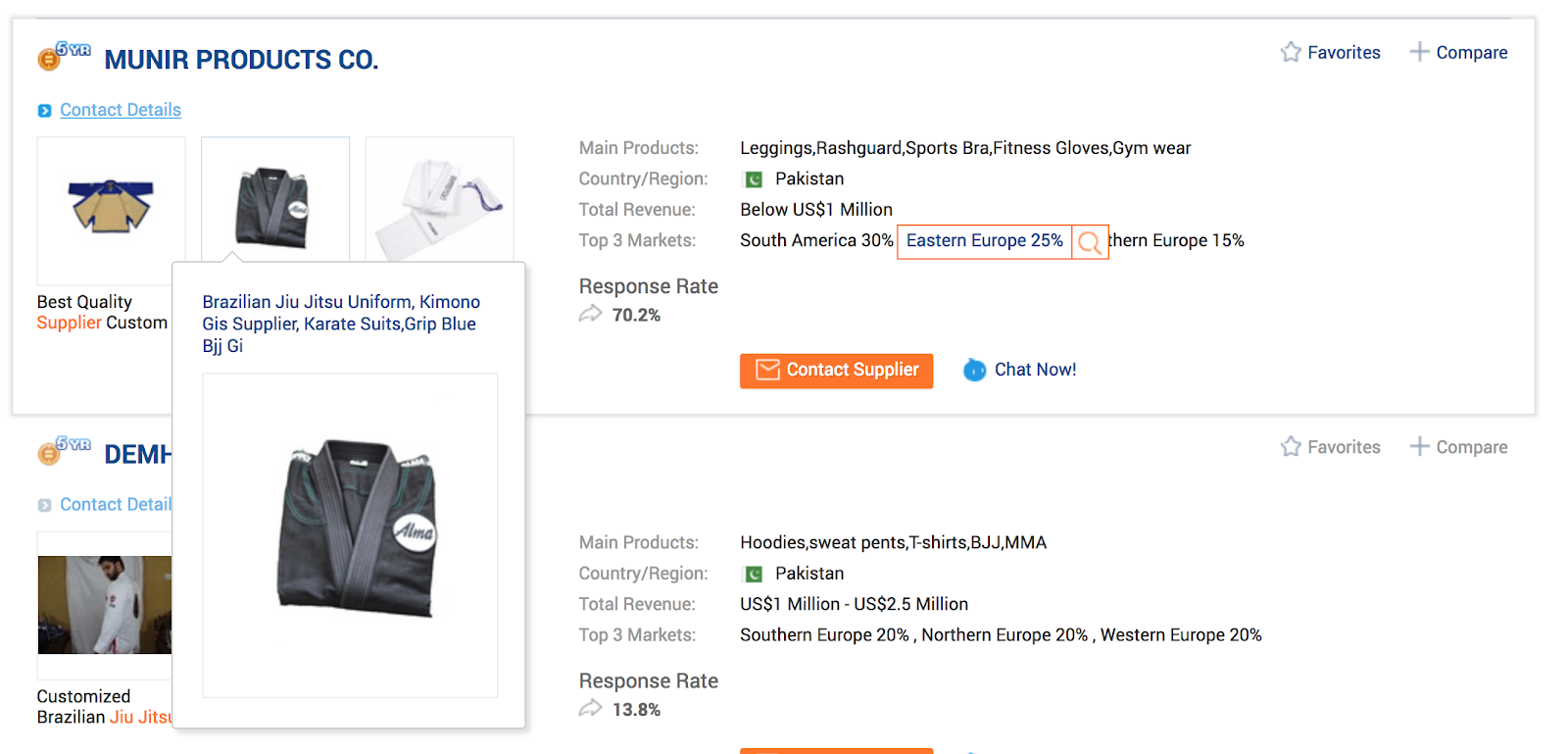

For example, let’s take a look at these two potential jiujitsu gi suppliers:

See a difference?

Of course not.

What if I told you that one supplier is one of the best producers of jiujitsu gis in the world? The other is total garbage. There is absolutely no difference on Alibaba and no way for people who’ve had a negative experience with them to let others know (to see which supplier is which, keep reading).

This is how Alibaba works. They don’t make their money from you, the physical product maker, but from the suppliers buying badges and credibility. I had no idea about that when I first started and made extremely costly mistakes.

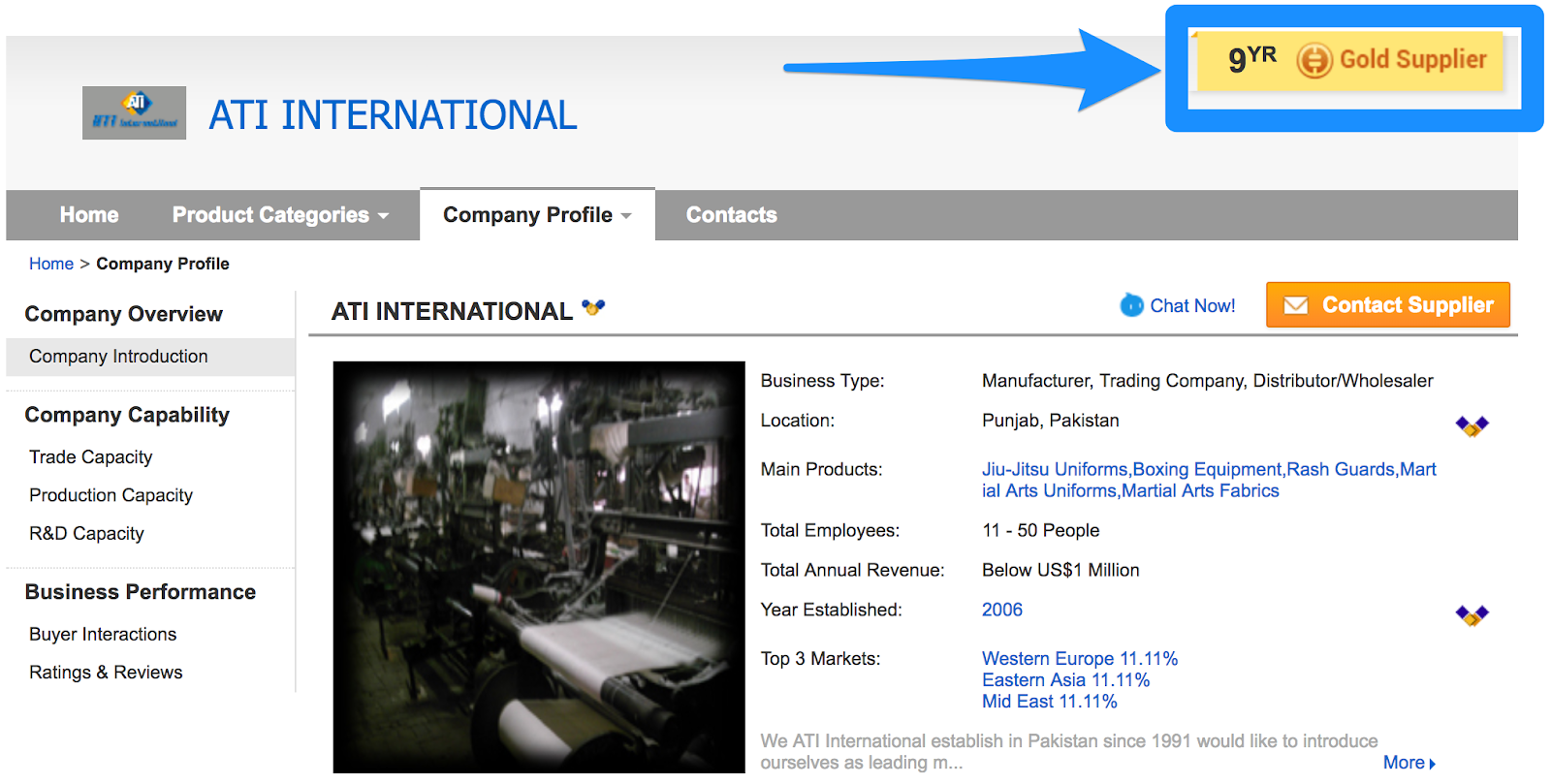

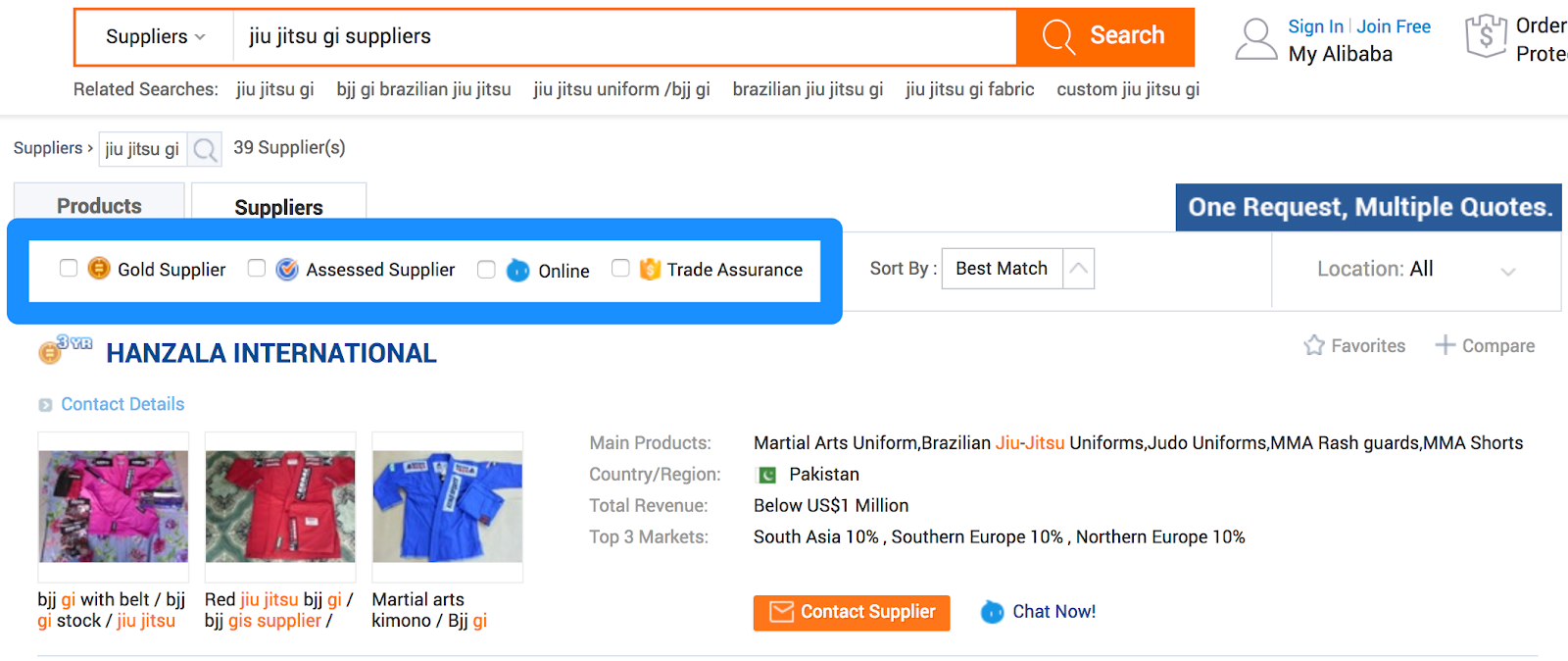

You’ll notice a bunch of badges and markers for each supplier. You’d THINK these would be helpful. But only certain ones are. Things to keep in mind:

- Remember that “Gold Supplier” means nothing in terms of your business, only how long they’ve paid Alibaba for being in their marketplace.

- Always check to see if they have “Alibaba Trade Assurance.” If your factory sends you the wrong items, defective items, or shorts you, you can file a dispute.

- Being an “Assessed Supplier” is a step in the right direction, but this depends wholly on Alibaba trusting a local agency to check them out, and to me, seems like it’s easily gamed.

From here, I always check for a few key things as red flags:

- Do they pretend to be the supplier of the top brand in your space?

- Are their images stock or stolen from another brand’s website? Check through a few listings and see if any of them are using the same images. Also, beware if you find a supplier using photos from all of the top brands in your industry. It’s doubtful they’re the supplier for them all and are allowed to use the images. Odds are, they’ve stolen them to siphon credibility.

For example, in the image below, I know that “Alma” is a very high-end brand that’s one of the few made exclusively in Japan. Since this factory listing is based in Pakistan, the fact that they are using the Alma image is a giant red flag:

Fun fact: What makes it even more of an epic-level red flag is that it’s actually MY image that they stole. I personally posted that image on my gi review website and they cropped out my living room carpet:

Other things to look for in the photos:

- Do they only have junky flip phone photos?

- Are there any actual photos of the manufacturing facility?

- Are the keywords accurate or stuffed with a bunch of random things?

- Do they claim they can “do everything”? For me, this meant they claimed to be experts at gis, sublimated rashguards, boxing gloves, etc. No factory has the facility built out to be good at all of those things. Odds are, if this is true, you’ve found some sort of middleman. Run. Away.

How to find the best suppliers on Alibaba

If you’re determined to use Alibaba, I recommend contacting as many suppliers as possible to start.

When you first search for your item, use the phrase “OEM” in your phrasing. OEM stands for “original equipment manufacturer.” There are a LOT of middlemen making their way into Alibaba who will pretend to be a factory, but they’re just operating at a coffee shop around the corner from a factory, and once they get a large order, may disappear into the night with your money.

Once you’re comfortable with a few, it’s time to vet them and start building a relationship.

How to find suppliers WITHOUT using Alibaba

This was my favorite discovery that I only found much later (after I’d already built a relationship with my supplier), but would’ve been powerful had I found it earlier.

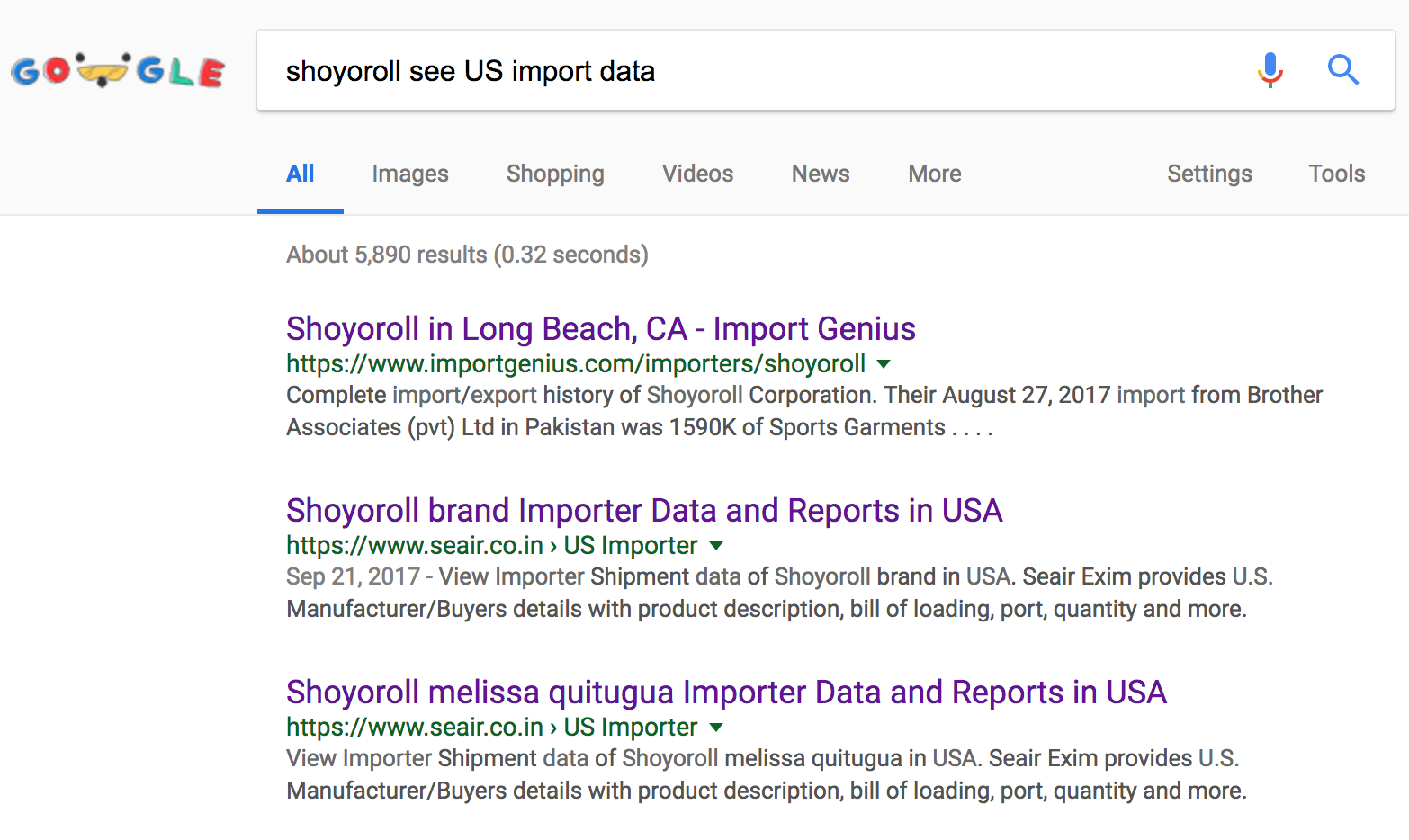

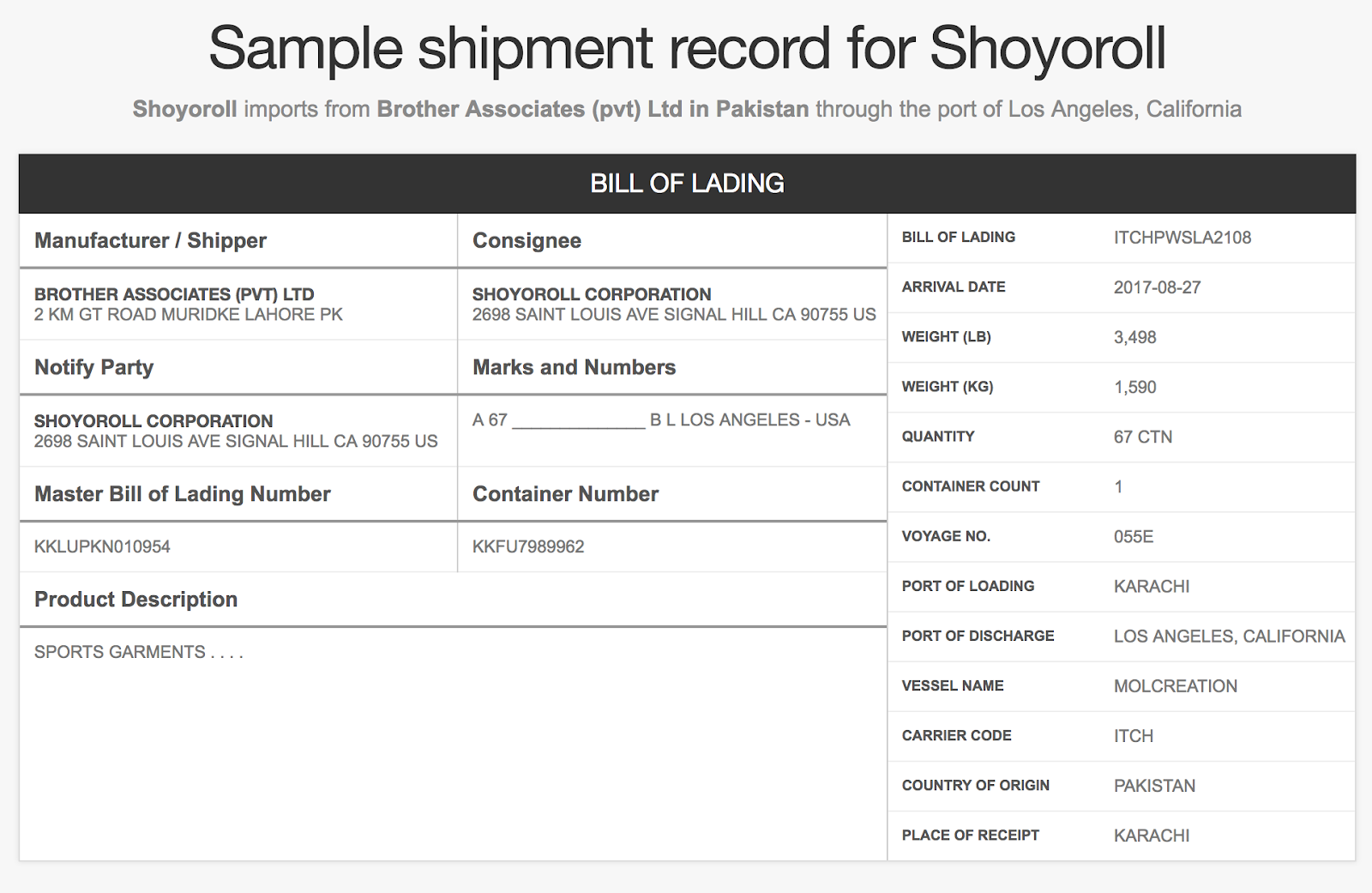

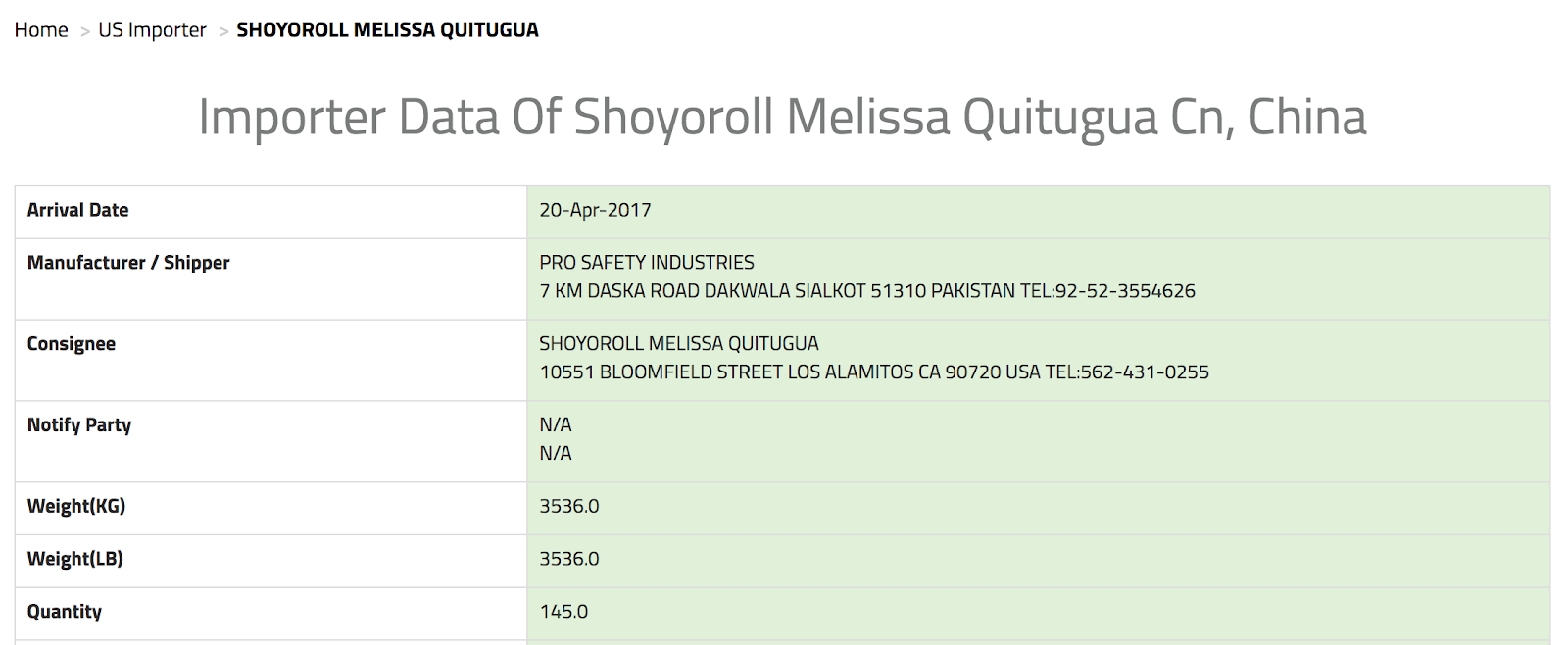

By simply Googling the largest brands in my industry with the added terms of “see US import data,” a number of third-party websites told me exactly who they were importing from, the amounts, and what the items were.

I was able to instantly discover the highly coveted supplier of one of my industry’s most sought-after brands.

I then checked those brands out in Alibaba and made sure they had a listing there.

One gem that this also uncovered was a brand that wasn’t heavily promoted on Alibaba (no “Gold Supplier” rating) and had a terrible website. This is often true of many import / export companies.

Why would this company need to advertise on Alibaba or via a marketing website when they’re already at capacity making items for some of the world’s biggest brands? It’s almost a trade secret that, for my industry (and maybe yours), the best suppliers aren’t on Alibaba because they don’t have to be.

…but you don’t have to take the same path as everyone else. How would it look if you designed a Rich Life on your own terms? Take our quiz and find out:

Vetting suppliers and getting samples / prototypes of your physical product

Admittedly, this is the largest hurdle when it comes to creating physical products. From t-shirts, to table tennis bats, to jiujitsu gis, you absolutely have to vet your suppliers and not rush into production.

Don’t commoditize your supplier when you’re first starting out. They aren’t a line item on your expense sheet. They’re your partner. You will live and die based on whether or not they can deliver the right goods on time and communicate effectively. Treat them like your co-founder.

This is going to be a relationship, and while it might not seem like it, clear communication is a supplier’s most important asset. Even if they make mistakes, their ability to understand what went wrong, and explain how they’ll fix it, will save you. Here’s how to vet your supplier:

1. Have them create a full-production sample of your product. They may try to send you a generic “factory” sample of what they make, but don’t accept it. You want a 100% complete working sample that you could sell to a customer today. Have them send samples until they have it 100% dialed in. Factories may try to short you in production costs any way they can, so if it looks like they misunderstood your instructions, take note. If they’re taking shortcuts, be wary.

The best way to get a manufacturer your designs is simply to email them all of the files together (in a single email). If the design can’t fit into a single email, it’s too complicated and I’d recommend breaking it down into smaller parts, refining each smaller part separately, and then going forward with the larger project.

The best advice that I can give on getting samples made is to be as specific as possible and always include visuals whenever possible (even if they’re hand-drawn).

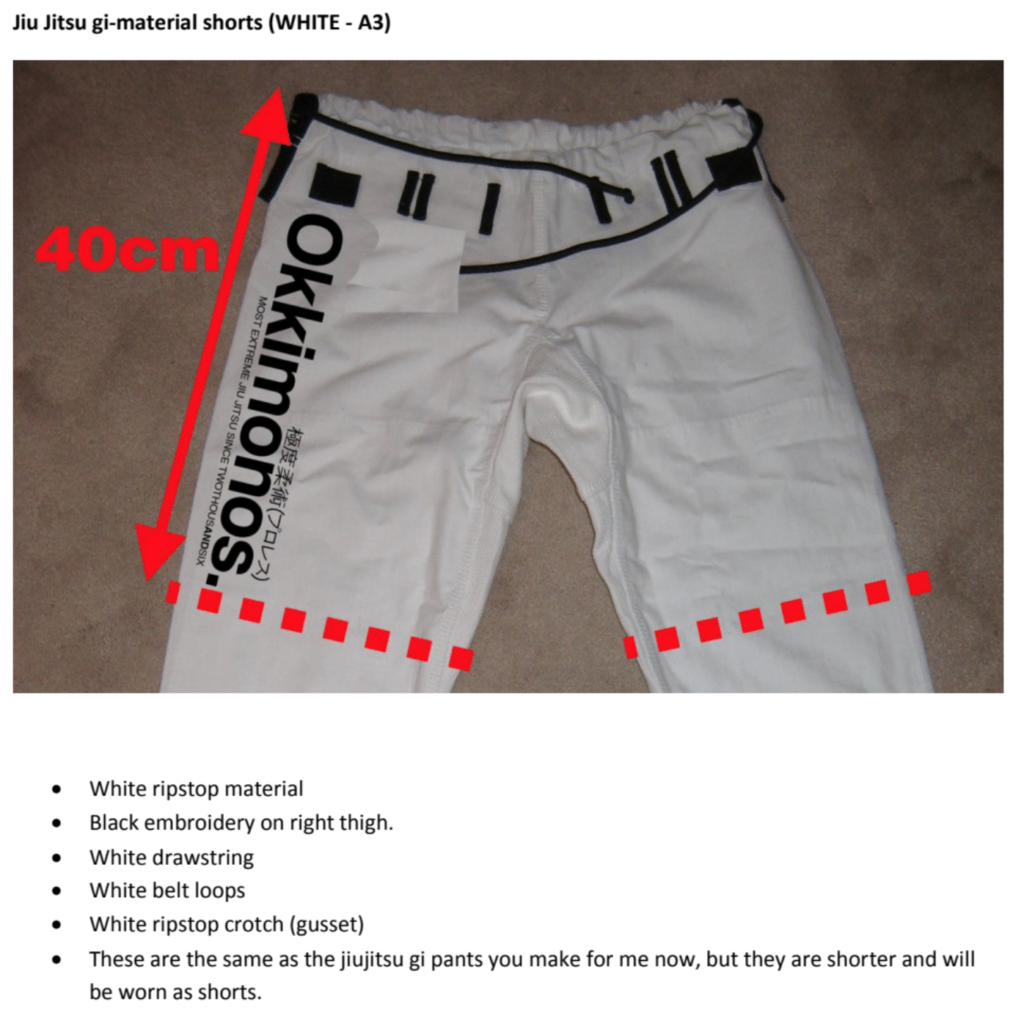

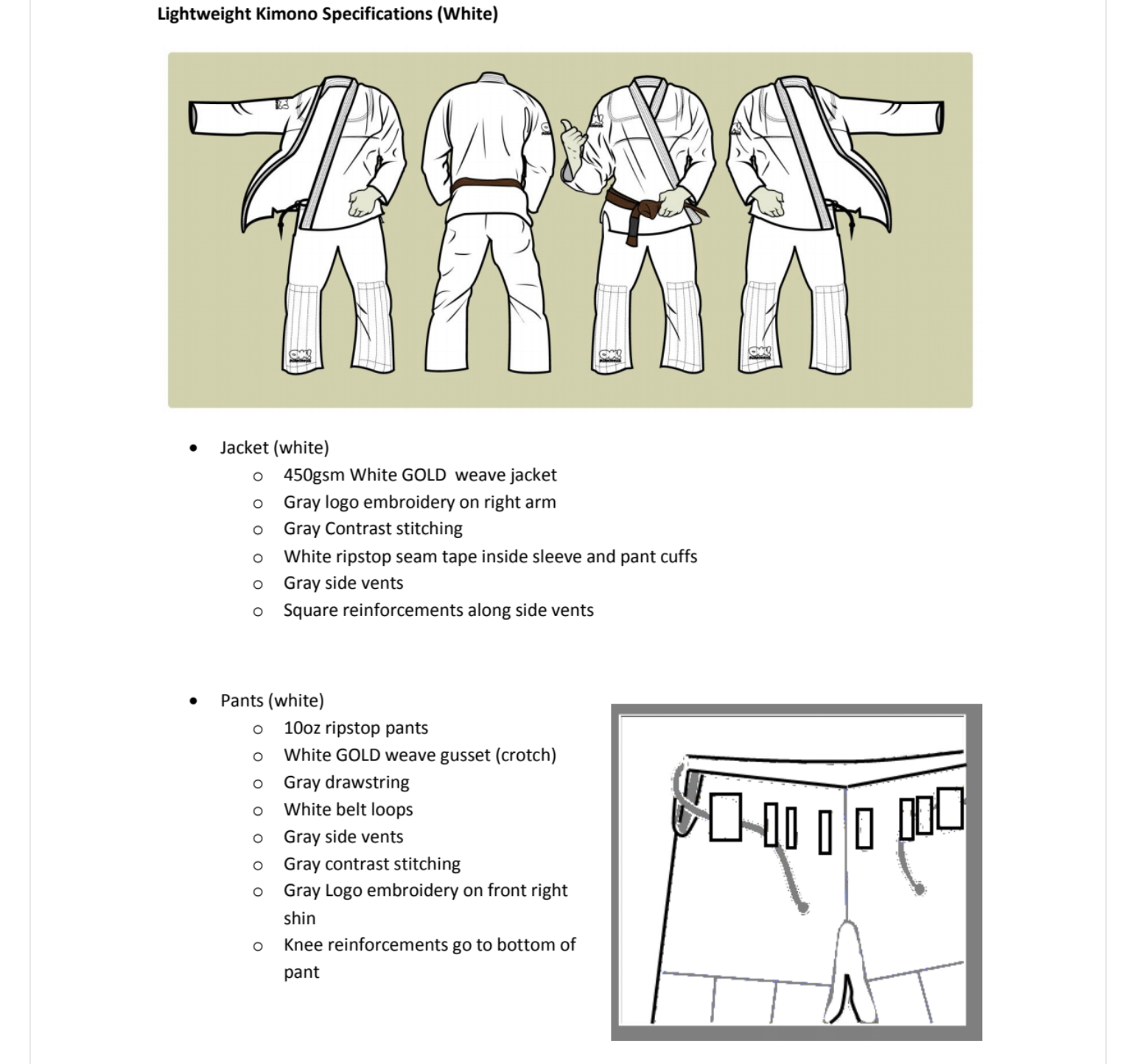

For example, here is a sample email mock-up that I sent to my manufacturer for a brand new product idea that I had:

You can see that I’ve used their measurement system (centimeters) and not mine (inches) to avoid confusion. Even after working with my manufacturer for years, things are still lost in translation.

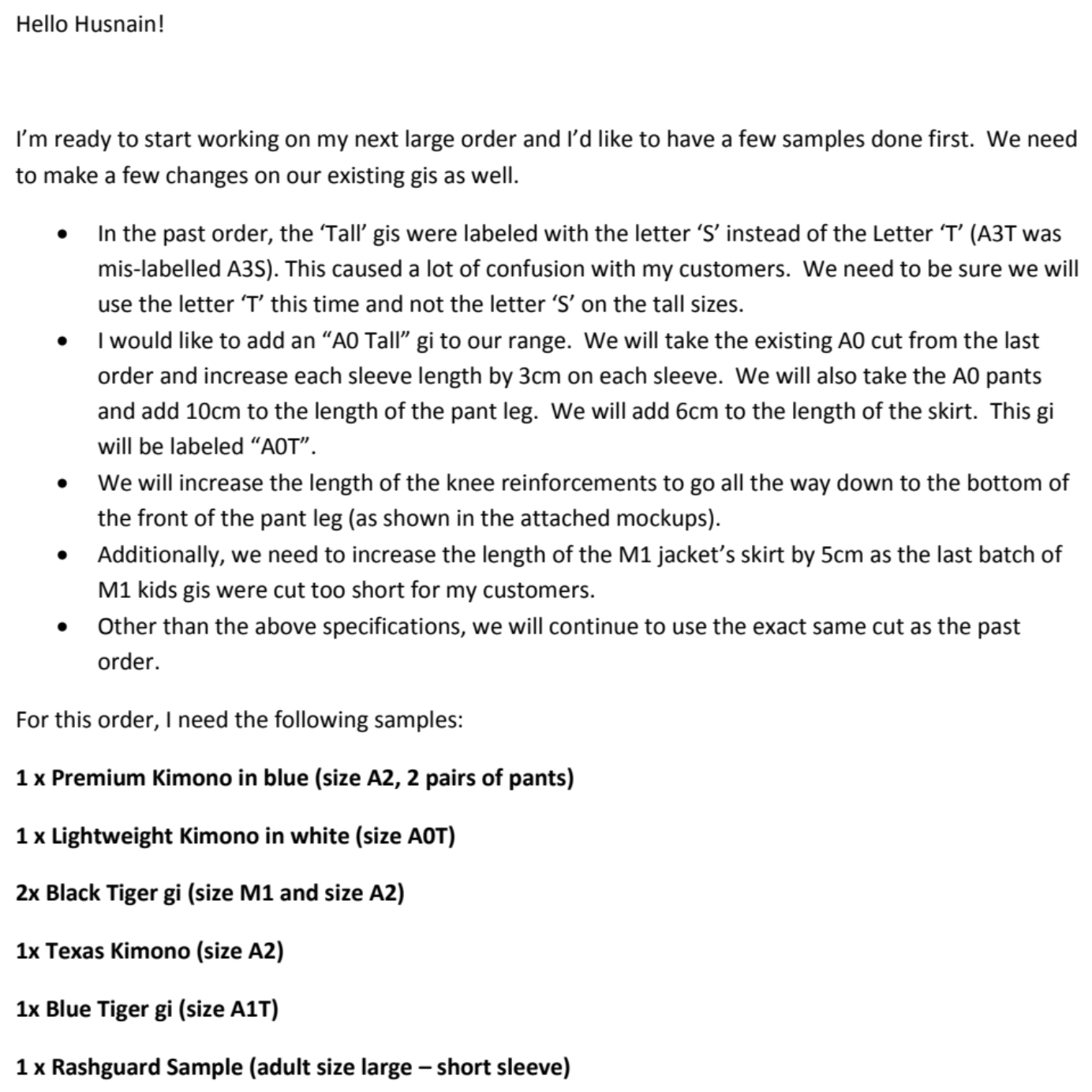

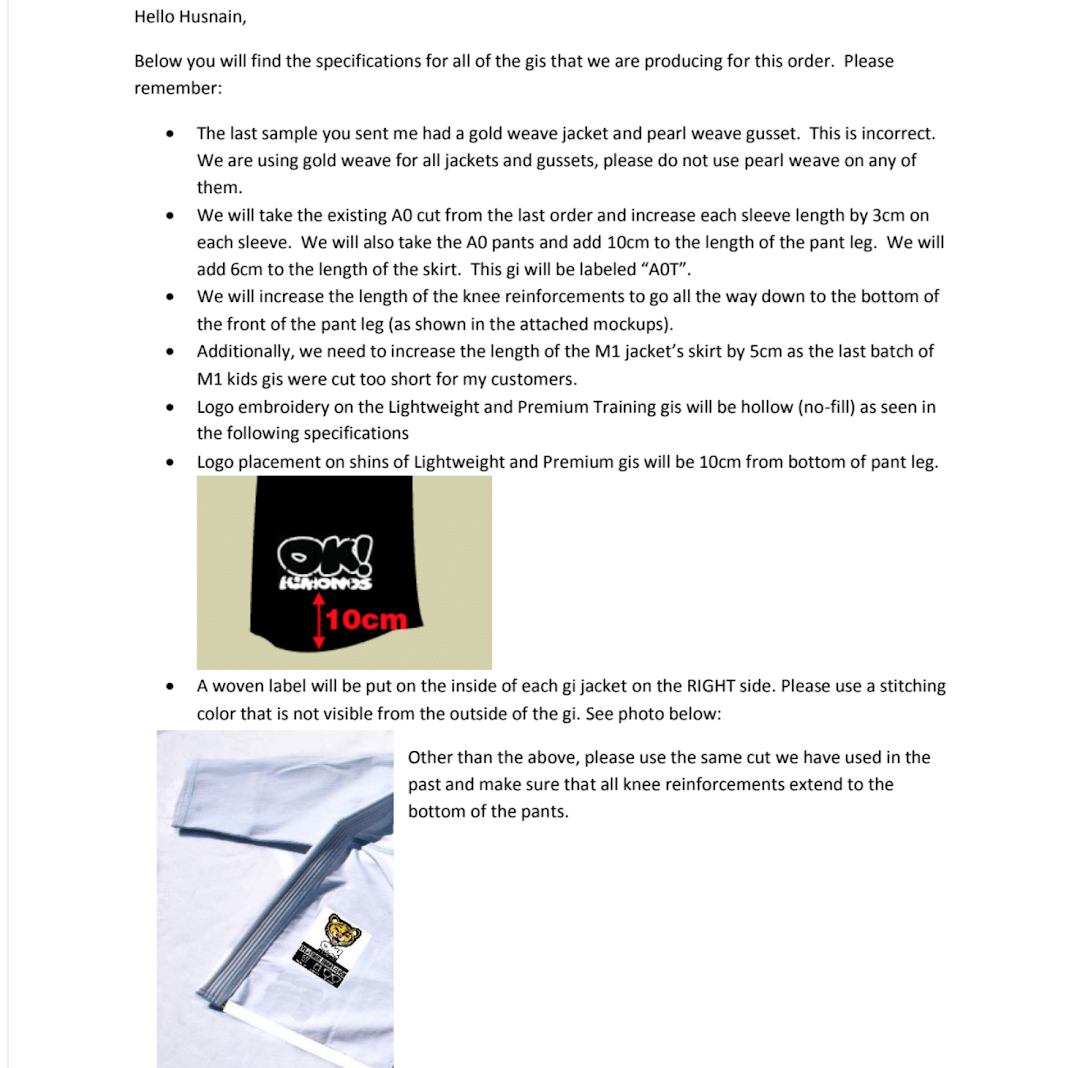

Here are a sample email and mock-up that went out for new order samples.

When the samples arrived and were not correct, I emailed my supplier back, again, with very specific directions.

The more places you can include information, the better. I included the same information in a PDF, an email, and even in the file names (naming a patch file “lapel tiger patch 15cm x 5cm.ai” to avoid any chance of confusion).

2. Create a small run. Once they have a perfect sample down, have them create a small run (10-20) of them and compare them to each other. How good is the quality control? How does one compare to the next?

Complete each of these steps across three to four different suppliers and choose who you work best with. Again, now that we’ve narrowed it down to suppliers who can create our product, who communicates the best? Who cared the most about you?

Please note, this will be expensive. And remember: this is the reason people prefer digital products. But paying more upfront gives you a strong foundation and it’ll save a lot of money in the long-run. I know, because I made the mistake of trying to save money upfront, only to spend more in the end.

When I started out, I thought I did everything right. I got a sample made from a few factories, chose the best one, and placed my order for the final product, the one I would send to my customers. My first orders had white and orange with a lot of custom embroidery. I was so excited. And when they arrived, I decided to do one last test: I took out two and threw them in the washer to see how they held up … and the colors bled everywhere. I ended up with white gis with orange all over them. I couldn’t send this to customers. I had just wasted my first real order.

How did this happen? My production gis from ATI International (the same one you saw above) were white and orange. My “factory” sample from ATI was generic and BLACK. Why did I wait until I had spent all of my money on my first order to wash the gi or see if the colors bled?

Because I’m an idiot.

Because I didn’t have this guide when I was starting out. Thoroughly test your product before putting it into production.

Making coffee cups? Use three of them for a week and take ten more and mail them to yourself or to a friend across the country. Do they make it through the shipping and testing phase in tact? Make sure your product can withstand all that you’ll be asking it to endure.

Negotiating price

When I started, I paid full price for everything. Only later did I realize that my Pakistani manufacturers inflated their prices 40-70% to account for the haggling that they expected to happen.

If you can’t negotiate on price, or don’t want to, a few other things you can negotiate are (more on each of these below):

- Shipping costs

- Lead time

- Minimum order requirements

Not familiar with the customs of the regions that you’ll be doing business in? I highly recommend checking out Derek Sivers’ Wood Egg books on moving to and doing business in eastern Asia and his import/export guide.

Manufacturing and production

When you’re starting out, minimum order requirements are going to be really important to know. You might not be able to make a profitable product until you’re able to order 1,000+ at a time, and unless you’re willing to take on investment to scale, or be patient for the next two years, you may not make it that far. How much are you willing to sacrifice your margins to get to market more quickly?

Lead time also matters quite a bit. Not only do we have to factor in how long it’s going to take the manufacturer to produce your product, but shipping and import times have to be factored in.

If you’ve done the smart thing and proven your product by taking money from a few customers ahead of time, having reasonable lead times for your buyers matters. Faster shipping cuts into your margins, and should you not factor in the cost and time required for importing goods, you could destroy your customer relationship.

Importing / customs

I’ve used both DHL and independent importing services. DHL was able to get my items to me much faster but at a much higher price. When I scaled up my orders to 250+ gis at a time, it made more sense to get the best margins possible, with slower shipping and (unexpectedly) a more unreliable timeline.

Shipping by boat from China or Pakistan (where my items were manufactured), took 6-8 weeks (one shipment took almost 10 weeks), whereas shipping by plane took 6-8 days. Ship by plane as long as possible, and when you have enough cash flow and a sustainable business model, consider importing by boat.

Customs obviously varies by country (I live in the USA), but I’ve had product stuck in imports for weeks, only to arrive with the boxes cut open and some of my product destroyed (they cut my gis apart) as import agents “checked” for illegal substances. Preparing for the unexpected and setting your expectations accordingly will protect you from most of the rookie mistakes I’ve made.

For example, I took pre-orders to the tune of about $3,000 and gave them an expected lead time of eight weeks. It’s a great way to get money upfront to fund the creation of a product (think: Kickstarter), but there’s some unseen risk.

Everything lined up in my head, but I hadn’t considered that my product might get stuck in customs (it did) or that the final samples that were set to arrive would be wrong (they were). The gis ended up taking 13 weeks to deliver and a few people were furious. The ones who didn’t send me rage emails never shopped with me again. All because I didn’t prepare for the unexpected.

Remember: with a digital product you’re fully in control of its distribution. With a physical product, it’s handled by people who don’t have your interests at heart. Customs agents, mail carriers, factory workers … they are crushingly ambivalent about whether your business succeeds or fails.

Refunds hurt a lot more with physical products. You get your item back (typically in an unsellable fashion) and the customer wants a refund for their initial shipping price as well. The smartest thing that I did was outline my return policy very clearly in both the ordering process and the order confirmation process.

Taking money first is great, and so are pre-orders (taking money before production), as long as you set your customer’s (and your own) expectations accordingly based on the knowledge of what can (and will) go wrong.

Let’s talk

I’m a GrowthLab reader, so I know most readers sell digital products. However, I’d love to leverage my expertise for you: the physical product maker. I sold my jiujitsu gi company, Ok! Kimonos, at the end of last year, and I’d love to share everything that I learned along the way as it applies to YOU. SO here’s my ask:

- If you’ve already started getting your product manufactured – What worked for you that I left out? Was there something that worked for you that’d be a game-changer for other readers? Let me know in the comments below.

- If you’re just getting started – Where are you getting hung up? What phase in your business are you finding yourself stuck at? Let me know in the comments below.

I’m looking forward to reading your comments. I’ll answer every single one.

If you liked this post, you’d LOVE our Ultimate Guide to Finding Your First Profitable Idea

It’s one of the best things I’ve published, and totally free – just tell me where to send it:

Host of Netflix’s “How To Get Rich” NYT Bestselling Author, & Host of the I Will Teach You To Be Rich Podcast. I’ll show you how to take control of your money with my proven strategies so you can live your RICH LIFE.

Written by Ramit Sethi

Host of Netflix’s “How To Get Rich” NYT Bestselling Author, & Host of the I Will Teach You To Be Rich Podcast. I’ll show you how to take control of your money with my proven strategies so you can live your RICH LIFE.